- 100% recycled

- Biodegradable

- Carbon neutral

- Compostable

- Recyclable

- Renewable

Bio-additive packaging

Polybags' range of standard bio-additive packaging is made from regular polythene - i.e. manufactured using oil-based polymers - with an additive that acts as a catalyst to accelerate the degradation process.

Polybags' range of standard bio-additive packaging is made from regular polythene - i.e. manufactured using oil-based polymers - with an additive that acts as a catalyst to accelerate the degradation process.

The additive - named TDPA (Totally Degradable Plastic Additives) and produced by EPI Environmental Technologies - is designed to manage the lifetime of polythene products so that, once their useful shelf life has passed, they will first degrade and then biodegrade into environmentally-benign products in a period of a few years, rather than decades or centuries.

This type of packaging is also referred to as 'degradable' or 'oxo-degradable' packaging. To find out more about Polybags' other environmentally-friendly packaging, please visit:

Related to bio-t packaging

Related to bio-t packaging Related to compostable packaging

Related to compostable packaging Related to eco-friendly packaging

Related to eco-friendly packaging

Related to biodegradable packaging

Related to biodegradable packaging

Related to recyclable packaging

Related to recyclable packaging

Buy eco-packaging now

Buy eco-packaging now

Regular polythene will degrade over time, although this process can take decades or even hundreds of years in a landfill site. The TDPA additive used in our bio-additive packaging ensures that this process is accelerated by a factor of hundreds or even thousands.

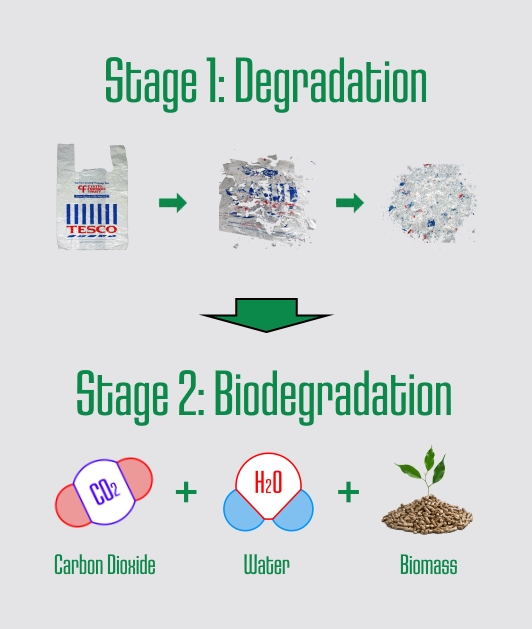

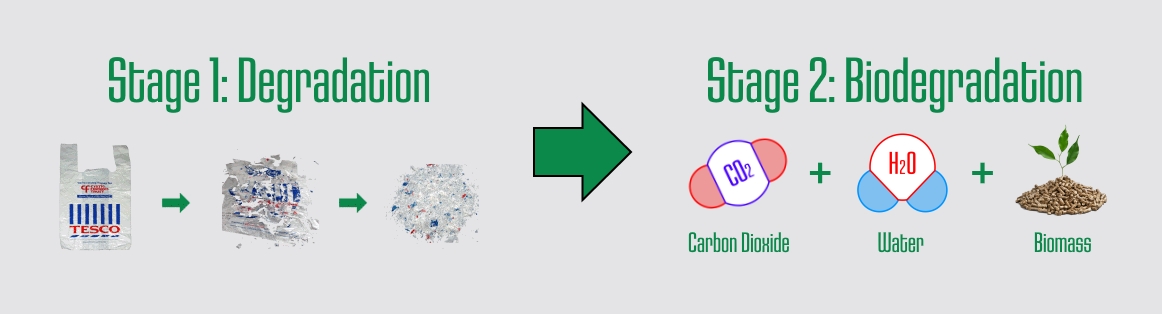

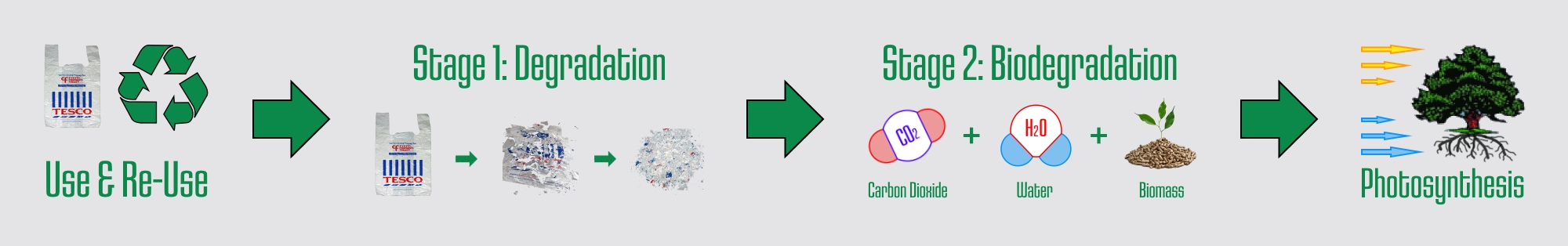

How bio-additive bags break down - a two-stage process

When oxo-biodegradable packaging is exposed to either sunlight, heat or mechanical stress - or a combination of these - a two-stage degradation process is triggered.

Stage 1: Oxidative degradation

The bio-additive acts as a catalyst to degradation - an irreversible process which is accelerated by heat, UV light and mechanical stress. The process causes polymer chain scission, which results in shorter-chain molecules and a reduction in molecular weight until the polythene is no longer a polymer, but a material which is inherently biodegradable in the environment.

Plastics containing the bio-additive are designed to degrade between 2-3 years, depending on the product applications and the disposal environment.

Stage 2: Biodegradation

During this stage - which can run simultaneously with or take place after Stage 1 - the degraded (oxidised) material is consumed by bacteria, fungi and microorganisms in the environment, and is converted into natural elements of carbon dioxide, water and humus.

The biodegradation rate will depend on the disposal environment, but independent testing has found polyethylene with the TDPA additive achieved 60% biodegradation in soil in less than two years.

Shelf life and storage instructions

Our bio-additive packaging has a shelf-life of one year from the date of manufacture, although the same additives that accelerate the degradation process also reduce this shelf life.

Our bio-additive packaging has a shelf-life of one year from the date of manufacture, although the same additives that accelerate the degradation process also reduce this shelf life.

We therefore advise that our bio-additive packaging is stored in a cool, dry place, away from direct exposure to sunlight, heat, humidity and moisture.

Testing and standards

Our bio-additive packaging - and other oxo-degradable plastics - are tested in accordance to British Standard 8472 and American Standard ASTM D6954 Standard Guide for Exposing and Testing Plastics that Degrade in the Environment by a Combination of Oxidation and Biodegradation.

Advantages of bio-additive packaging

- Cheaper than starch-based compostable packaging

- Stronger than starch-based compostable packaging

- Similar properties to regular polythene packaging prior to the onset of degradation

- Ideal for single-use or limited-life-cycle applications

- Polythene products with TDPA additives evaluated and tested to oxo-biodegradable standards, including International Standard ASTM D6954 and British Standard 8472

- Food safe - compliant with European Union (EU) and US standards

- No adverse toxicological effects or by-products

- Recyclable (pre- and post-consumer) and reusable until noticeable breakdown

- Degrades in a landfill environment, ultimately taking up less landfill space

Disadvantages of bio-additive packaging

- Made using non-renewable fossil fuel

- Takes longer to degrade than starch-based compostable packaging

- Shelf life of just 12 months - reduced if left in direct sunlight or heat

- Not certified as compostable according to EU standard EN13432

- Degradation depends on conditions of heat, light, moisture, mechanical stress and/or microbes

- Can not be sold to customers in the EU

Exports to the EU

Due to EU legislation, bio-additive products containing the TDPA oxo-degradable additive can no longer be sold in Europe.

EU directive 2019/904 has banned a range of single-use plastic items - including cotton bud sticks, cutlery, chopsticks, plates, stirrers, straws, balloon sticks, oxo-degradable plastics and expanded polystyrene (EPS) food and beverage containers - from entering the EU market.

As a result, Polybags is unable to sell bio-additive products to customers in the EU. We recommend trying our range of compostable products instead.

Further information

For more information on how our bio-additive biodegradable bags work, please visit the website of EPI Environmental Technologies at epi-global.com.

FREE DELIVERY

400mm wide x 500mm length, 55 micron thickness. (Medium Parcel A3).

From £31.86 per 200

Bio and 100%-recycled mailing bags in low quantity handypacks.