660mm wide (with gusset opening up to 1168mm wide) x 660mm long, 20 micron thickness

From £36.67 per 250

- 100% recycled

- Biodegradable

- Carbon neutral

- Compostable

- Recyclable

- Renewable

Recyclable packaging

Polybags is a responsible packaging manufacturer. As well as producing a range of biodegradable bags and packaging with recycled content, we also produce a huge range of products made from recyclable materials, such as polythene and paper.

Polybags is a responsible packaging manufacturer. As well as producing a range of biodegradable bags and packaging with recycled content, we also produce a huge range of products made from recyclable materials, such as polythene and paper.

By re-using and then recycling the packaging we use - rather than just disposing of it after a single use - we can all help to reduce waste and save on raw materials, thereby cutting greenhouse gas emissions and contributing to a greener, cleaner planet.

Look out for the green universal recycling logo (above) as you shop at Polybags. If the product features it - as most of ours do - then it is suitable for recycling. If your local recycling collection doesn't include polythene bags, our handy recycling locator tool will help you find your nearest plastic bag recycling point (UK only).

Find your nearest recycling point

Find your nearest recycling point  Related to recycled packaging

Related to recycled packaging

Related to eco-friendly packaging

Related to eco-friendly packaging

Related to paper packaging

Related to paper packaging

Related to renewable packaging

Related to renewable packaging

Buy eco-packaging now

Buy eco-packaging now

What products can I recycle?

The vast majority of Polybags products can be recycled. On this website, any product marked with the universal green recycling icon is suitable for recycling.

The vast majority of Polybags products can be recycled. On this website, any product marked with the universal green recycling icon is suitable for recycling.

If your local recycling collection doesn't accept polythene bags, our recycling locator tool will help you find your nearest bag recycling point (UK only).

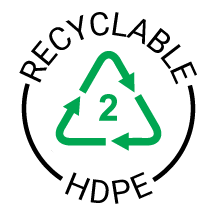

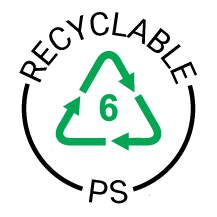

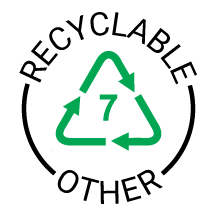

Within the recycling symbol you will most likely see a number - this number is an identification code that is part of a universal recycling system.

Numbers 1-6 specify a particular plastic resin from which a product is made, whilst any other plastic that doesn't fit into one these categories is labelled '7 Other'. Numbers 20-22 relate to paper products.

Most of Polybags' recyclable plastic products are made from polyethylene - either low density (LDPE) or high density (HDPE) - or polypropylene. You can find out more in our handy recyclable plastics guide, below.

Recyclable plastics used by Polybags

Polyethylene Terephthalate (PETE or PET)

Polyethylene Terephthalate, or PET (or PETE), is a strong, clear, lightweight plastic that belongs to the polyester family.

Polyethylene Terephthalate, or PET (or PETE), is a strong, clear, lightweight plastic that belongs to the polyester family.

PET can be used to make a wide range of packaging and is best known for making plastic drinks bottles, but it can also be used to make polyester - a soft and flexible fabric.

- Polybags products include: Food packaging lids

- Wider uses include: Plastic drink bottles (e.g. water, fizzy drinks, fruit juice), food containers (e.g. honey, olive oil, salad dressing), bottles for cleaning products (e.g. spray detergent, fabric softener)

- Uses after recycling: Fleece clothing, tote bags, furniture, carpets

High Density Polyethylene (HDPE)

High density polyethylene, or HDPE, is a lightweight but very strong plastic that is both incredibly versatile and extremely malleable.

High density polyethylene, or HDPE, is a lightweight but very strong plastic that is both incredibly versatile and extremely malleable.

As a result, this typically opaque plastic is used for a huge range of products, in both its rigid form (e.g. milk cartons) and its flexible form (e.g. bags), making it one of the most widely-used types of plastic today.

- Polybags products include: Vest carrier bags, food/produce bags & sheets, polythene gloves, dog poo bags

- Wider uses include: Milk bottles/cartons, shampoo bottles, food containers (e.g. margarine tubs, yoghurt pots, salt dispensers)

- Uses after recycling: Storage containers, plastic lumber, patio furniture, rubbish bins, recycling bins etc.

Low Density Polyethylene (LDPE)

Low density polyethylene, or LDPE, is a strong, translucent, flexible and moisture-resistant plastic that is easy to process and low in cost.

Low density polyethylene, or LDPE, is a strong, translucent, flexible and moisture-resistant plastic that is easy to process and low in cost.

Offering excellent product protection, LDPE is most commonly used for film packaging and is one of the popular forms of plastic packaging in the world, as well as the most widely-used material here at Polybags.

- Polybags products include: Mailing bags, carrier bags (other than vest carriers), packing bags, grip seal bags, layflat tubing, builders rolls, waste bags, garment & laundry covers, biodegradable bags

- Wider uses include: Toys, squeezable bottles, food packaging, pipes (e.g. water & gas), wire & cable covering

- Uses after recycling: Plastic lumber, panelling, compost bins

Polypropylene (PP)

Polypropylene, or PP, is a strong, tough, moisture-resistant and versatile plastic that is used for similar applications as polyethylenes, but is generally stiffer and more heat-resistant. PP is the world's second-most widely produced plastic, after polyethylene.

Polypropylene, or PP, is a strong, tough, moisture-resistant and versatile plastic that is used for similar applications as polyethylenes, but is generally stiffer and more heat-resistant. PP is the world's second-most widely produced plastic, after polyethylene.

Polypropylene film has the appearance of cellophane, but is cheaper, stronger, more eco-friendly, has better clarity and makes higher-quality products.

- Polybags products include: Glossy display bags & film, greeting card bags, sweet bags, film front bags, flower sleeves

- Wider uses include: Food containers (e.g. yoghurt, margarine) and bottles (e.g. ketchup), medicine containers, car parts

- Uses after recycling: Waste bins, plastic brooms, flower pots, ice scrapers

Polystyrene (PS)

Polystyrene, or PS, is commonly-used plastic that can be found in either solid (molded) or foamed form.

Polystyrene, or PS, is commonly-used plastic that can be found in either solid (molded) or foamed form.

A naturally clear plastic, PS in its solid form is generally hard and somewhat brittle. PS foam is a good insulator and has good damping properties. Most people would be familiar with expanded polystyrene (EPS) - a rigid, tough, closed-cell foam that offers good protection when used in packaging.

- Polybags products include: Loose fill chips, loose fill beads

- Wider uses include: Protective packaging, bicycle helmets, compact disc (CD) cases, egg cartons, disposable plates/cups, take-away food containers

- Uses after recycling: Thermal insulation, foam packaging, egg cartons

Other recyclable plastics

Vinyl (V or PVC)

Polyvinyl chloride, more commonly known as PVC or vinyl (V), is the third most widely-produced plastic in the world, after polyethylene (PE) and polypropylene (PP).

Polyvinyl chloride, more commonly known as PVC or vinyl (V), is the third most widely-produced plastic in the world, after polyethylene (PE) and polypropylene (PP).

PVC comes in either as a rigid plastic - e.g. as used to make window frames - or in a more flexible form, such as that used to make clothing and music records.

- Uses include: Shampoo bottles, piping and cable insulation, inflatables, clothing, bank & credit cards, window and door frames

- Uses after recycling: Packaging, paneling, decking, insulation, flooring, speed bumps

Other plastics (O)

The plastic resin identifier code 7 is given to all plastics that don't fit into any of one of the other six main categories.

The plastic resin identifier code 7 is given to all plastics that don't fit into any of one of the other six main categories.

Polybags' range of vacuum pouch bags are manufactured from a composite film made from polyamide (PA) and polyethylene (PE), meaning they are classified in this category.

- Polybags products include: Vacuum pouch bags

Recyclable paper & cardboard

Paper and cardboard are popular alternatives to plastic for a range of products where the functional benefits of plastic - e.g. flexibility & moisture resistance - are not required.

Paper and cardboard are more widely recyclable and decompose much quicker than plastic, so are less likely to be a source of litter. However, when it comes to production and transportation, paper or cardboard have a much higher carbon footprint than plastic.

Polybags sells a wide range of paper products, all of which can be recycled into other paper-based products.

These products are identifiable on the Polybags website by one of the following icons, which correspond to one of three recycling categories:

Paper recycling

Paper is one of the most widely-used materials on the planet, something we use so often in our day-to-day lives.

Paper is one of the most widely-used materials on the planet, something we use so often in our day-to-day lives.

Polybags stocks a wide range of paper bags and other paper-based products - all of which are recyclable.

- Polybags products include: Paper carrier bags, paper mailing bags, paper packing bags, paper grocery gags, kraft paper rolls, hexa paper rolls, paper flower sleeves, paper waste sacks

- Wider uses include: Printing (books, newspapers, magazines), writing, art & craft, packaging, decorating, cleaning

Paperboard recycling

Non-corrugated fiberboard - more commonly known as paperboard - is a paper-based material that is thicker than paper, offering superior strength and rigidity.

Non-corrugated fiberboard - more commonly known as paperboard - is a paper-based material that is thicker than paper, offering superior strength and rigidity.

Paperboard is a popular packaging material, as it is lightweight, strong and can be easily cut and formed.

- Polybags products include: Solid cardboard mailers

- Wider uses include: Food packaging (cereal boxes, snack boxes), general purpose packaging

Cardboard recycling

Corrugated fiberboard - more commonly known as cardboard - is a popular packaging material.

Corrugated fiberboard - more commonly known as cardboard - is a popular packaging material.

Whilst the term 'cardboard' is often used as a generic term to describe any form of heavy paper pulp–based board, corrugated cardboard consists of a fluted or corrugated layer of board, either attached to a flat board (single face) or sandwiched between two flat boards (single wall).

Corrugated cardboard may also feature more two corrugated sheets between three flat boards (double wall) or three corrugated sheets between four flat boards (triple wall).

- Polybags products include: M-range expandable cardboard mailers, large letter postal boxes, e-commerce boxes, small parcel boxes

- Wider uses include: Cardboard boxes

Products with limited recyclability

Products displaying this icon are recyclable, but they require specialist recycling facilities to do so.

Products displaying this icon are recyclable, but they require specialist recycling facilities to do so.

Takeaway coffee cups, for example, are made of paperboard that is coated in a thin layer of polythene. These materials are both recyclable, as is the cup itself, technically, but only a limited number of UK facilities are able to process coffee cups due to the combination of materials.

Polybags' range of kraft food packaging offers the same challenge when it comes to recycling. These products are recyclable, but only a limited number of facilities will be able to process them.

As with all recyclable products - and even moreso in this instance - we recommend that you check locally to see if these items can be recycled in your area.

- Polybags products include: Kraft takeaway boxes, kraft food tubs, kraft food containers, kraft food bowls

- Wider uses include: Coffee cups, takeaway cups, other food packaging

Where can I recycle my packaging?

Use Polybags' recycling locator tool to find your nearest recycling point.

Use Polybags' recycling locator tool to find your nearest recycling point.

The way that we recycle products is always changing, as technology evolves and more local authorities widen their recycling programmes.

Most people now have a home recycling service available to them, to collect a range of recyclable packaging, including paper, aluminium, glass and plastic.

Most kerbside recycling programmes have traditionally restricted plastic recycling to rigid plastics such as bottles or trays, although more local authorities are now beginning to collect plastic bags as part of this service.

For those UK households unable to recycle plastic bags and film in their home recycling, Polybags' recycling locator tool provides a quick and easy way to find your nearest bag recycling point. These are often located at major supermarkets.

The recycling locator tool also allows you to check exactly what packaging your local authority permits in each of the recycling bins. Just enter your postcode and away you go!

FREE DELIVERY

230mm wide x 318mm length, 55 micron thickness. (Large Letter A4).

From £16.81 per 200

Bio and 100%-recycled mailing bags in low quantity handypacks.