230mm wide x 325mm long, 37.5 micron thickness (C4 for A4)

From £37.37 per 1000

- 100% recycled

- Biodegradable

- Carbon neutral

- Compostable

- Recyclable

- Renewable

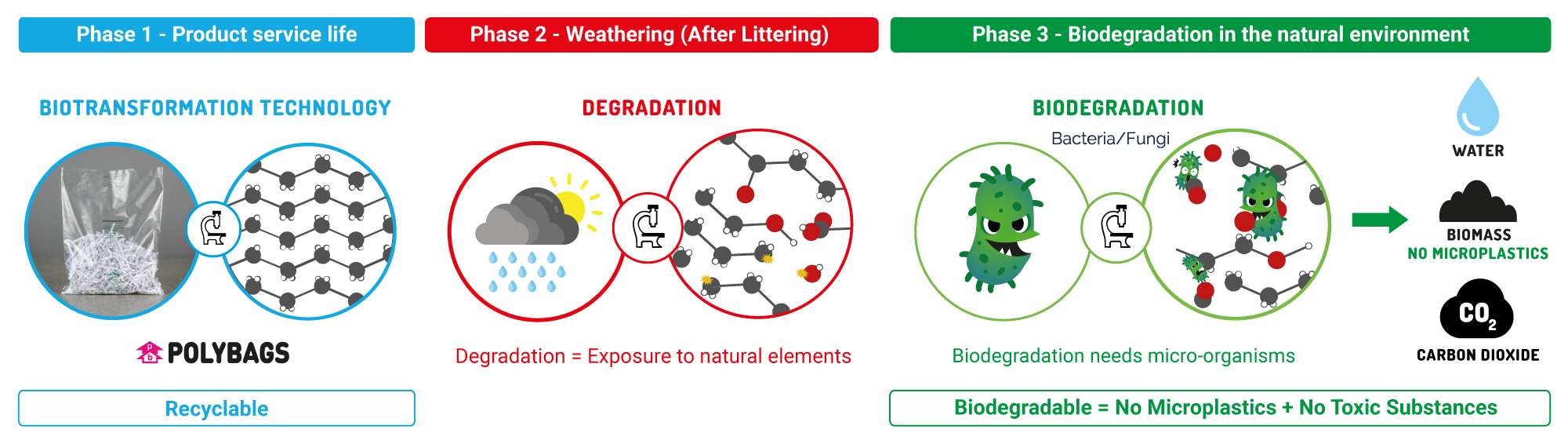

Biotransformation packaging

Polybags' new range of biodegradable packaging is made from regular polythene with a biotransformation (Bio-T) additive that accelerates the degradation process and is scientifically-proven to biodegrade without producing any microplastics.

Polybags' new range of biodegradable packaging is made from regular polythene with a biotransformation (Bio-T) additive that accelerates the degradation process and is scientifically-proven to biodegrade without producing any microplastics.

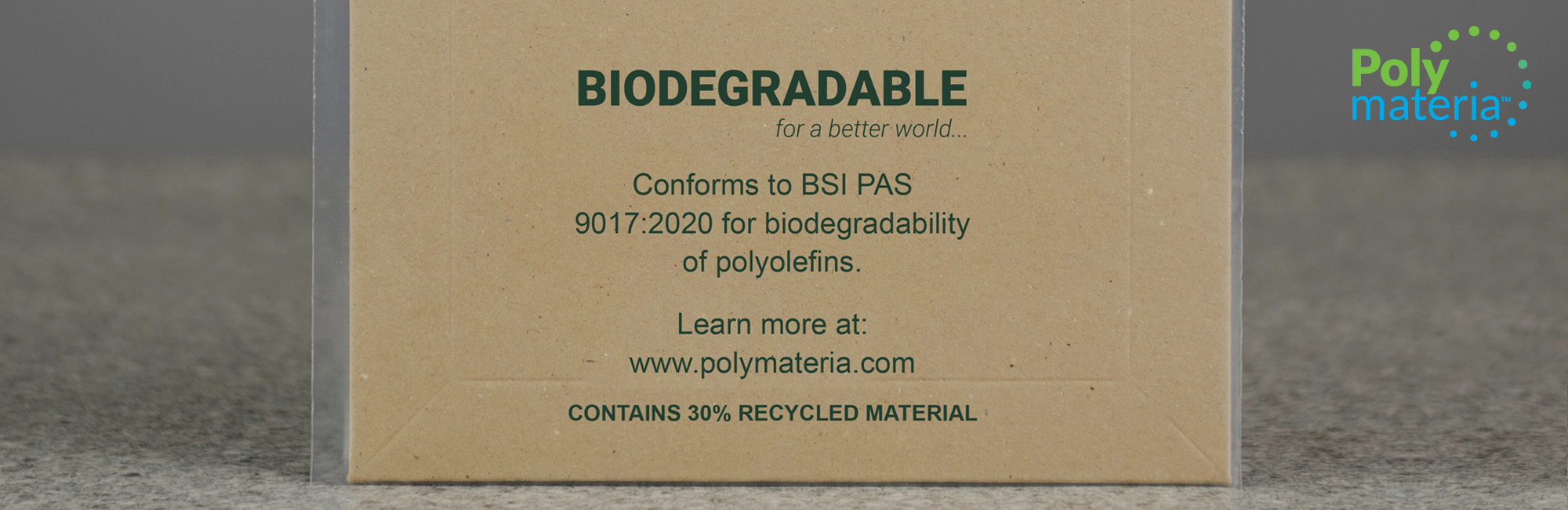

The additive - produced by Polymateria - uses 'time-set' biodegradation, where the product remains recyclable during its service life but, in the unwanted event of littering, will break down and biodegrade into naturally-benign materials in an open-air environment.

All material used by Polybags containing this additive has been scientifically-proven to biodegrade in the open environment and is compliant with standard PAS 9017:2000 on the weathering of polyolefins - as issued by the British Standards Institute (BSI).

Related to bio-additive packaging

Related to bio-additive packaging

Related to compostable packaging

Related to compostable packaging Related to eco-friendly packaging

Related to eco-friendly packaging

Related to biodegradable packaging

Related to biodegradable packaging

Related to recyclable packaging

Related to recyclable packaging

Buy eco-packaging now

Buy eco-packaging now

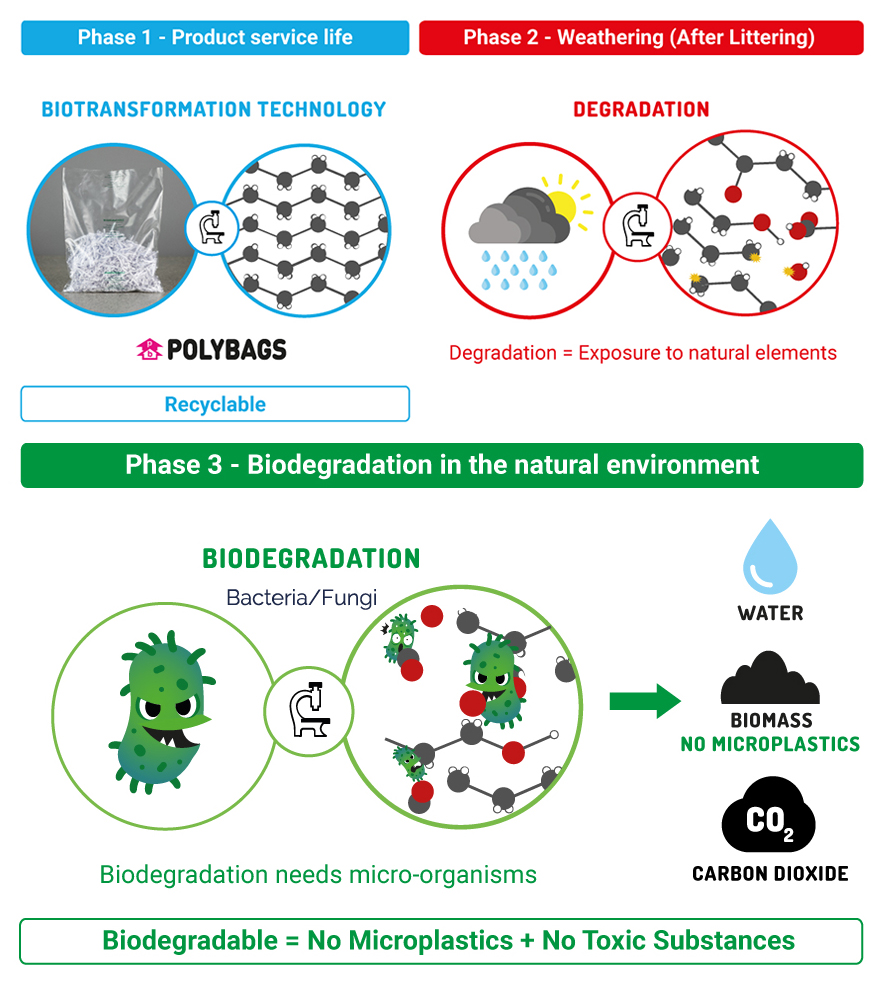

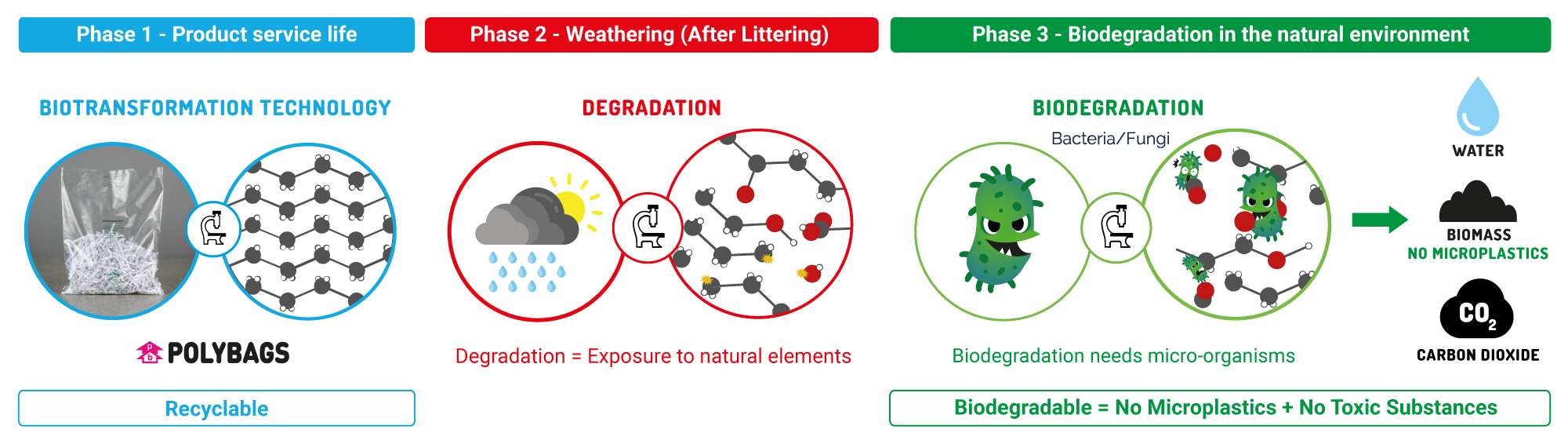

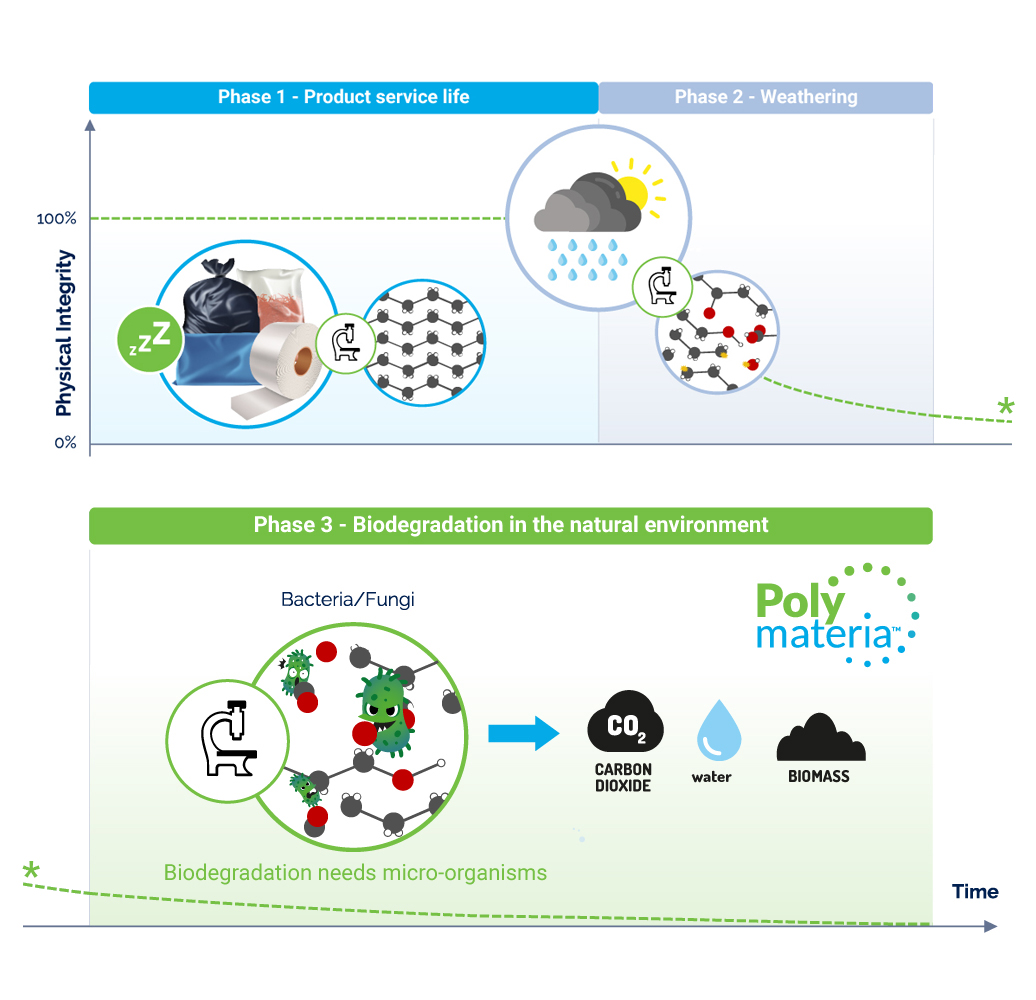

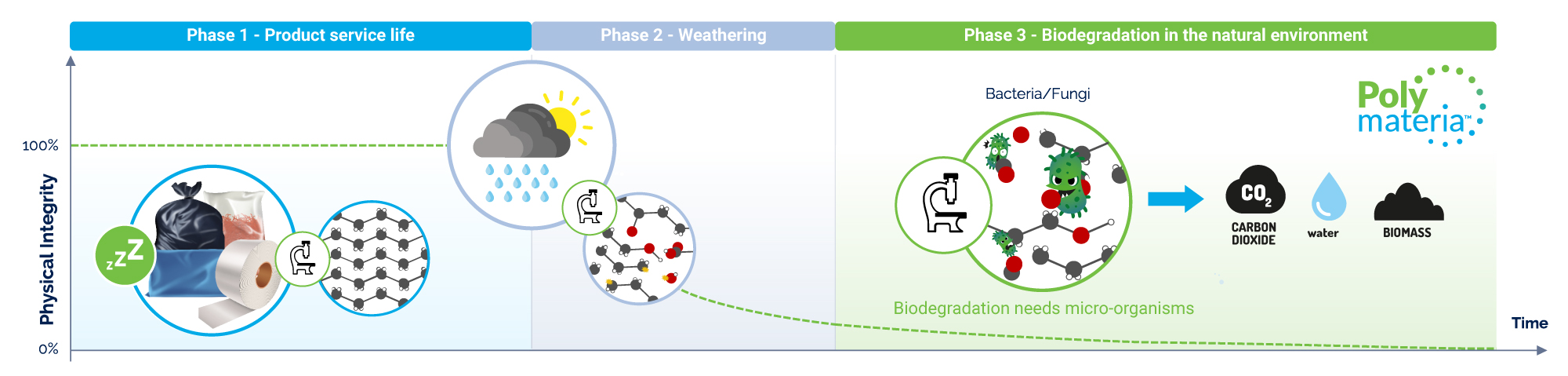

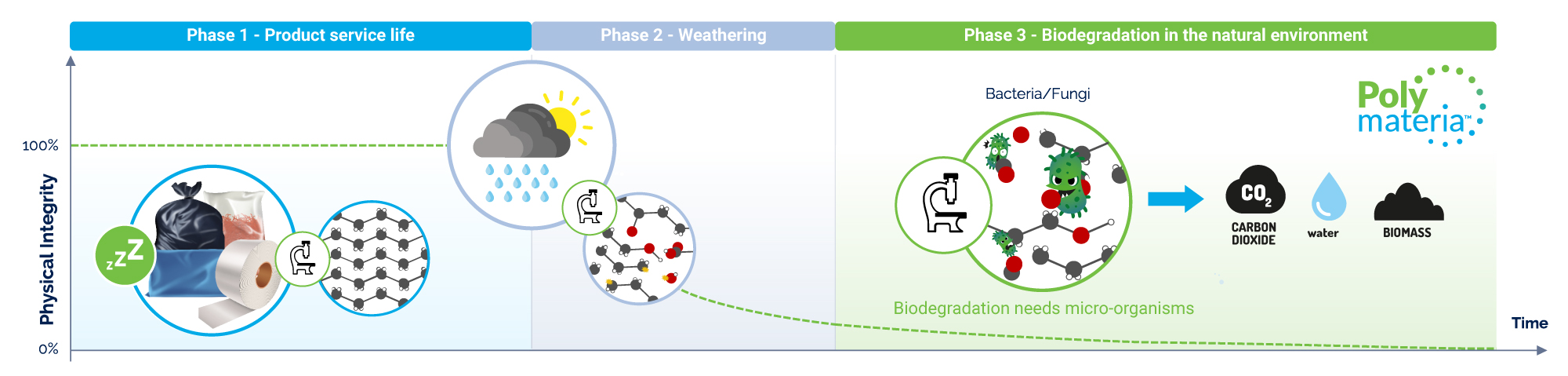

Biotransformation - a three-phase process

Regular polythene can take decades or hundreds of years to degrade. Polymateria's biotransformation (Bio-T) additive - which can be added as a masterbatch during the manufacturing process - means that products containing the additive retain the properties of regular polythene and can be recycled like regular polythene, but will also fully biodegrade in the natural environment were they to escape refuse streams.

Here is a brief explanation of how the revolutionary additive can achieve full biodegradation without harming recycling and enabling the circular economy.

Phase 1: Product service life

During the packaging's service life, the Bio-T technology is dormant and the packaging retains all of the functionalities of regular polythene. It can also be recycled just like regular soft polythene packaging, in the same recycling streams.

Phase 2: Weathering

The material structure has been engineered so that, in the event of littering, exposure to natural environmental conditions such as sunlight, air and water will cause the material to self-destruct. The Bio-T technology attacks the crystalline and amorphous region of the polymer structure, transforming it into a waxy substance that is no longer a plastic.

Ecotoxicity tests have demonstrated that this wax-like substance is not harmful to the environment, whether it comes into contact with soil, plants or the aquatic environment.

Phase 3: Biodegradation in the natural environment

Bacteria and fungi in the natural environment then digest the wax and break it down into carbon dioxide, water and humus. Third-party laboratory testing has found that polyethylene and polypropylene films containing the biotransformation technology will fully biodegrade within 1-2 years, leaving no microplastics behind.

Biodegradation testing measures the conversion of carbon in the test material to carbon in carbon dioxide (as per international standards ASTM D5988 and ISO 17556). A biodegradation rate of more than 90% is internationally-accepted to demonstrate complete biodegradation, with the remaining material converted to water and biomass.

PAS 9017:2020 - the new biodegradable plastic standard

PAS 9017:2020 is a new British standard for biodegradable plastic, launched by the British Standards Institute.

More specifically, the standard measures the biodegradability of polyolefins in the open-air terrestrial environment. Polyolefins are a family of thermoplastics that include polyethylene and polypropylene - the most commonly-used plastics.

The new standard addresses a significant gap in the plastics landscape to ensure claims about biodegradability can be independently verified without causing any harm to the environment.

The standard has strict pass/fail criteria to measure the biodegradability of polyolefins in an open-air environment without creating microplastics or causing ecotoxicity issues.

Storage instructions and shelf life

Prior to use, it is recommended that our biotransformation bags are stored in their original packaging between 17-23°C, away from direct sunlight and used within 12 months from the date of purchase.

Prior to use, it is recommended that our biotransformation bags are stored in their original packaging between 17-23°C, away from direct sunlight and used within 12 months from the date of purchase.

Failure to store the packaging as advised can reduce its shelf life.

Advantages of biotransformation (Bio-T) packaging

- Similar properties to regular polythene during product service life

- Reusable and recyclable in existing waste streams (alongside regular polythene packaging)

- Meets BSI standard PAS 9017:2020 on biodegradability of polyolefins

- Will biodegrade in the open environment in the event of littering

- Leaves no microplastics behind

- Passes ecotoxicity tests - not harmful to the environment

- Cheaper than compostable (starch-based) packaging

- Stronger than compostable (starch-based) packaging

- Food-safe

Disadvantages of biotransformation (Bio-T) packaging

- Produced using non-renewable fossil fuels

- Takes longer to degrade than compostable (starch-based) packaging

- Not suitable for industrial composting (does not meet EU compostable standard EN13432)

- Not suitable for home composting

Further information

For more information on how the biotransformation technology in our new Bio-T bags work, please visit the Polymateria website at polymateria.com.

FREE DELIVERY

375mm wide x 450mm high x 40 micron thickness, with 75mm bottom gusset

From £24.45 per 250

Bio and 100%-recycled mailing bags in low quantity handypacks.